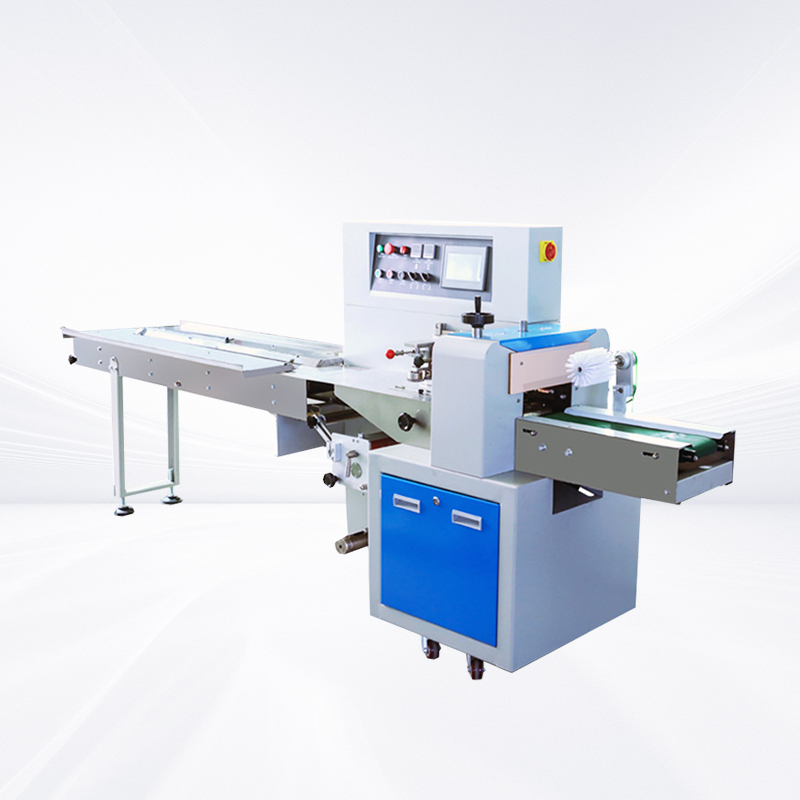

To maintain a pillow packaging machine used for packaging finished hookah charcoal and ensure its normal operation and extend its lifespan, regular maintenance and upkeep are necessary.

Cleaning and Hygiene: Regularly clean the machine’s interior and exterior surfaces, especially the parts that come in contact with the product. Periodically clean residues on the conveyor belt, rollers, and other moving components.

Lubrication: Periodically inspect and lubricate the machine’s moving parts to reduce friction and wear.

Electrical System: Regularly inspect the electrical circuits and connections to ensure safe and stable electrical supply. Periodically clean and check sensors and controllers to ensure their proper operation.

Replacement of Worn Parts: Regularly check the wear and tear of components such as blades, sealing strips, and other susceptible parts, and replace them as needed.

Regular Calibration: Periodically calibrate the machine to ensure the speed and precision of its various components. Adjust sensors and control systems as necessary to maintain high-quality packaging.

Regular Inspection and Maintenance of the Work Platform: Inspect the stability and safety of the work platform regularly to ensure operator safety. Periodically check the machine’s foundational support structures to prevent any potential structural issues.

Data Backup: Regularly back up the control system and operational data to prevent data loss or damage.

carbonization machine,charcoal making machine

carbonization machine,charcoal making machine