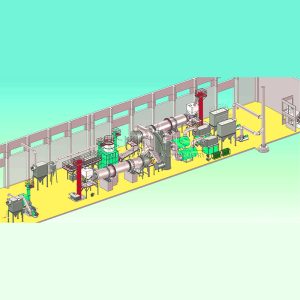

Una linea di produzione continua di carbone da biomassa è un insieme di apparecchiature utilizzate per convertire materiali da biomassa come il legno, paglia, e rifiuti vegetali in biochar. Si tratta di un sistema di produzione industriale utilizzato per la produzione su larga scala di prodotti carbonizzati.

Una tipica linea di produzione continua di carbone da biomassa può includere i seguenti componenti chiave:

- Sistema di lavorazione delle materie prime: Questa sezione riguarda la prelavorazione delle materie prime, tipicamente compresa la frantumazione, essiccazione o rimozione di impurità da materiali particellari.

- Forno di carbonizzazione: Trasferire le materie prime secche nel forno di carbonizzazione preriscaldato, che è il componente principale della linea di produzione di carbone da biomassa. Nel forno di carbonizzazione, Le materie prime subiscono pirolisi ad alte temperature, produzione di gas di sottoprodotto e carbone di legna da biomassa solida.

- Raffreddamento e raccolta: Il biochar prodotto dopo la carbonizzazione deve essere raffreddato e quindi può essere raccolto e immagazzinato. Allo stesso tempo, I gas raccolti possono essere recuperati e utilizzati.

- Raffinazione e confezionamento: Il biochar può essere ulteriormente perfezionato e lavorato per soddisfare i requisiti di varie applicazioni. I prodotti finali del biochar possono essere confezionati e venduti.

- Sistema di controllo: Le linee di produzione continua di carbone a biomassa utilizzano sistemi di controllo PLC per monitorare e regolare le condizioni di reazione al fine di garantire la qualità del prodotto e l'efficienza della produzione.

macchina di carbonizzazione,macchina per la produzione di carbone di legna

macchina di carbonizzazione,macchina per la produzione di carbone di legna