A grinding machine is an industrial equipment used to grind or crush raw materials into powder or fine particles. Grinding machines are suitable for various powder preparations, such as raw material minerals, gypsum minerals, coal, and other materials. They have a three-dimensional structure, a small footprint, and strong system integration. From bulk materials to finished powders, they form an independent production system.

- 제품 세부 정보

- 특징

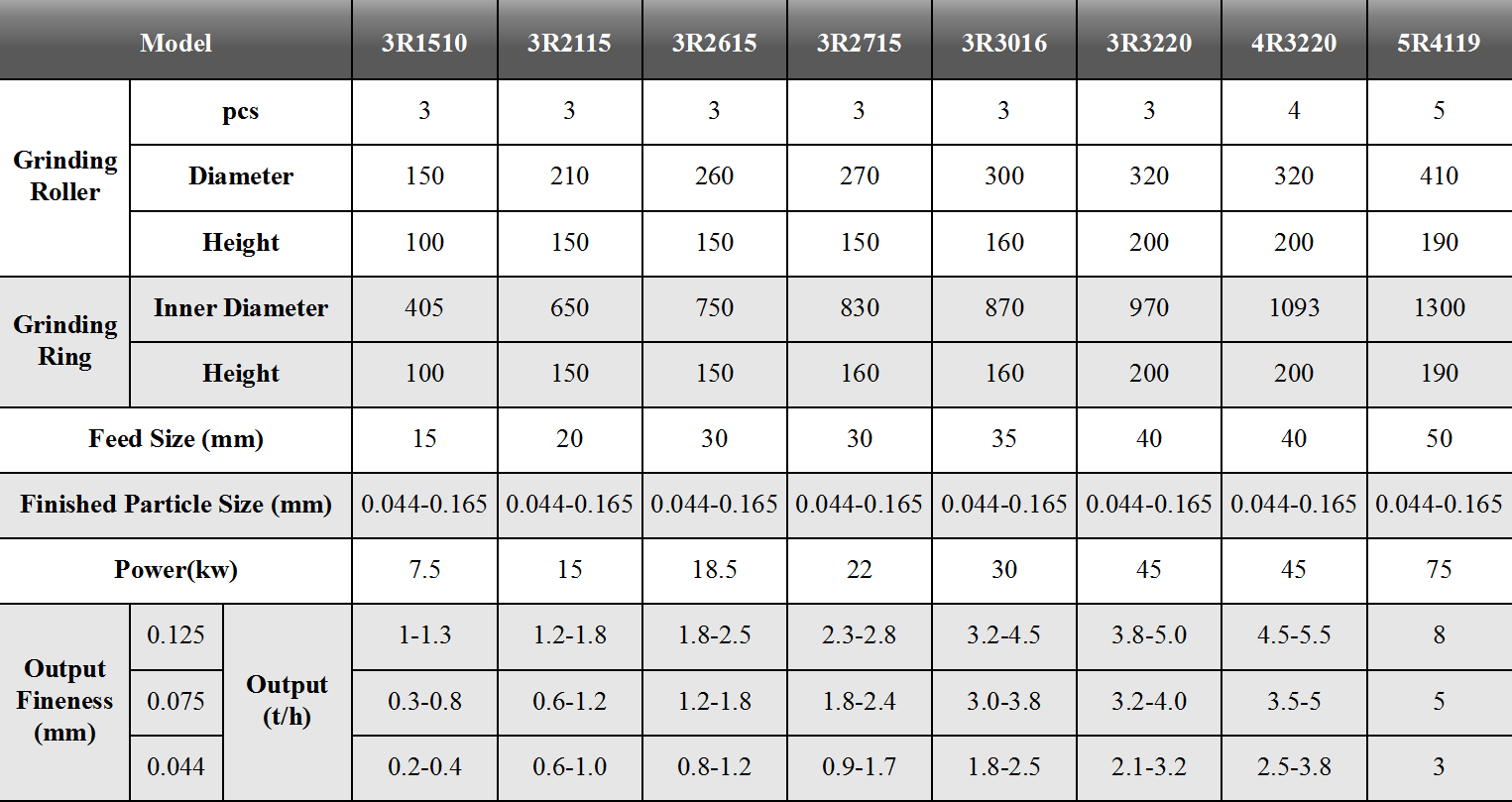

- 매개 변수

- 신청

- 문의

- This machine has the characteristics of high efficiency, low energy consumption, 작은 설치 공간, and low capital investment, making it widely used in the grinding and processing of mineral products and materials in various fields such as charcoal making, construction, and so on.

- The material is fed into the main grinding chamber of the machine for milling. After grinding, the powdered material is carried away by the airflow generated by a fan, then it undergoes classification through an analyzer.

- The powder that meets the required fineness is carried by the airflow through a pipeline into a large cyclone collector for separation and collection. It is then discharged through a powder pipe as the finished product powder.

- The finished product powder has uniform fineness and a sieving rate of 99%, which is difficult for other milling equipment to achieve.

- The main transmission unit of the milling machine uses a sealed gearbox and pulley, ensuring smooth transmission and reliable operation.

This type of machine finds extensive applications across multiple industrial sectors, suitable for the high-precision powder processing of hundreds of materials, including pebble, granite, basalt, quartz stone, iron ore, limestone, calcite, dolomite, fluorite, talc, gypsum, bentonite, coal, 잔, and fertilizers.

These materials’ Mons’ hardness scales should not exceed 9.3 and moisture content should be below 6%, and they should be non-flammable and non-explosive in nature.

이전: 듀얼 샤프트 슈레더

다음: 금속 슈레더

탄화 기계,숯 만드는 기계

탄화 기계,숯 만드는 기계