Ball press is an industrial equipment typically used to compress powdered or granular materials into solid products with spherical or other shapes. This type of equipment finds wide-ranging applications in various industrial sectors, including charcoal making, metallurgy, chemicals, agriculture, and food processing. The operating principle involves applying high pressure to compress the raw materials into the desired shape. This can be achieved through mechanical force or hydraulic systems, depending on the design and intended use of the equipment.

- Product Details

- Feature

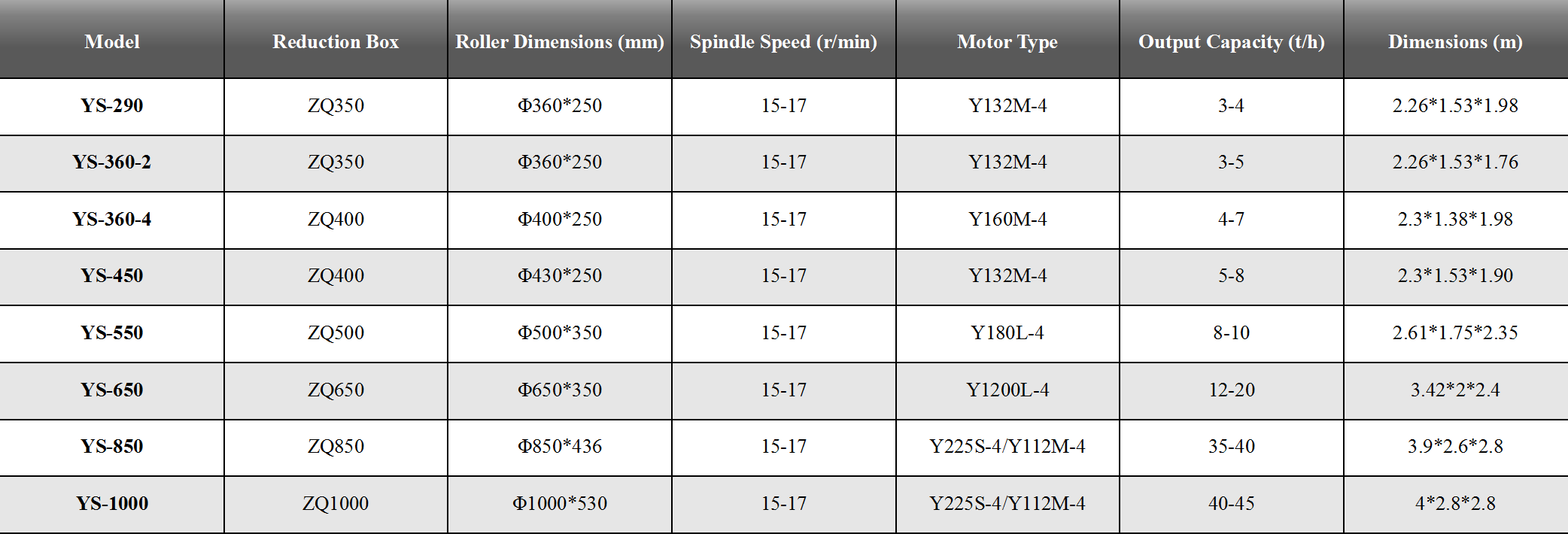

- Parameter

- Application

- Inquiry

- Comparing with other similar products, the ball pressing machine has obvious advantages such as high ball formation rate, low power consumption, compact structure, easy maintenance and debugging.

- A typical machine comprises a feeding system to introduce the raw materials into the machine, a compression section to shape the materials into balls, and a discharge system to eject the finished balls.

- It has diverse molding shapes, using 65 manganese steel casting, has long wear life, can be customized according to demand.

- This machine has high forming rate, and there is no need for drying, it uses roller pressing forming and products are successfully made one-time.

The applications are diverse, It can be used to press coal powder, iron powder, aluminum powder, rubber carbon black, lead carbon, talc powder, dry powder and so on. The performance and capacity of these machines may vary depending on the model and manufacturer.

Prev: Briquetting Machine

Next: Rod Extruder

carbonization machine,charcoal making machine

carbonization machine,charcoal making machine