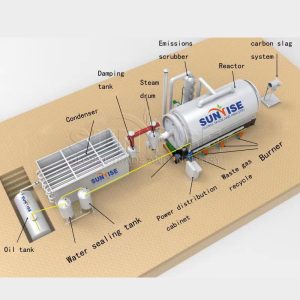

Pyrolysis plant refers to the apparatus used for the pyrolysis process, typically comprising high-temperature reactors and corresponding control systems. This equipment is utilized under conditions of oxygen deficiency to break down organic substances into gaseous, liquid, and solid products. Such equipment finds extensive applications in waste treatment, biomass energy production, and other related fields.

- Pre-processing: The steel wire is pulled out of the tires using a wire pulling machine. If necessary, it needs to be crushed into small pieces of 2-5 cm using a crusher after wire pulling.

- Feeding: A spiral feeder conveys tire chunks into the reactor.

- Pyrolysis: Ignite the fuel in the combustion chamber to heat the reactor. When the internal temperature of the reactor reaches 160°c, oil and gas are generated and enter the gas holder.

- Oil and gas separation: In the gas holder, heavy substances in the oil and gas settle and are liquefied into crude oil, which is stored in the crude oil tank. The light oil and gas rise and uniformly enter the condenser. In the condenser, the light oil and gas are liquefied into fuel oil, stored in the light oil tank. In the water seal, combustible gases are desulfurized and purified, then recovered and utilized to provide heat. In the flue gas condenser, the hot smoke is cooled and then enters the dust removal system. In the dust removal system, after four layers of filtration through water washing, spraying, porcelain ring adsorption, and activated carbon adsorption, the exhaust gas can meet emission standards.

- Slag discharge: Carbon black is discharged through an automatic slag discharging machine. Some of the steel wire in the tire chunks is also automatically discharged, then separated by a magnetic separator, and the steel wire and carbon black are conveyed to the discharge warehouse.

carbonization machine,charcoal making machine

carbonization machine,charcoal making machine