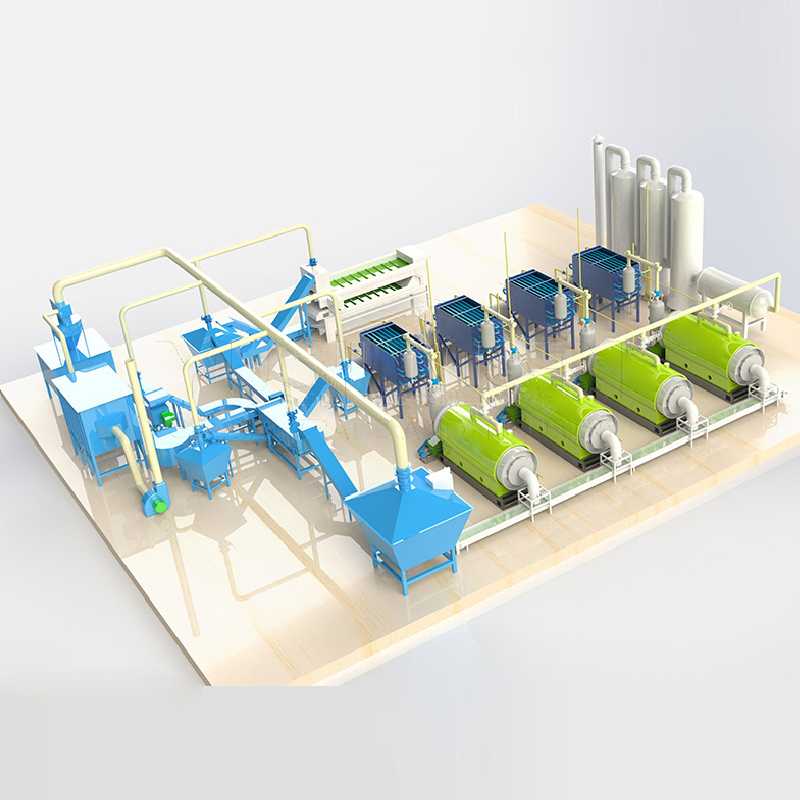

Solar panel processing equipment utilizes physical crushing and sorting to extract highly marketable silicon powder, copper powder, and plastic. The general process for recycling photovoltaic modules involves three main stages:

1.Disassembly of components through machinery or manual labor to remove the back panel, wires, and aluminum frame.

2.Crushing the components to eliminate toughened glass.

3.Crushing and sorting the remaining solar panel to extract metals and plastics.

Discarded solar panels enter a shredder for tearing, and the shredded materials go through a specialized crusher for further breakdown, dispersing eva film and monocrystalline silicon wafers. The dispersed materials, propelled by a fan, enter a collecting device, and after sorting, silicon is separated. The remaining mixed materials then go through a specialized grinder, followed by entry into an air flow screening device through a closed air system. Through a combination of airflow and vibration, non-ferrous metals and plastics are collected, and the dust generated by the airflow separation machine is also collected.

carbonization machine,charcoal making machine

carbonization machine,charcoal making machine