Линия по производству древесного угля периодического действия состоит из ряда оборудования и процессов, предназначенных для производства древесного угля партиями из исходного сырья. Этот тип производственной линии часто используется мелкими или кустарными производителями древесного угля и подходит для преобразования различных видов биомассы в древесный уголь. Угольная машина периодического действия не приспособлена к сырью насыпной плотности, например, опилки, рисовая шелуха, и так далее. Однако, Из сельскохозяйственных отходов с плотностью насыпи можно сделать некоторые формы, такие как стержень, квадрат или шар, а затем введите угольную печь периодического типа, чтобы получить древесный уголь.

- Подробнее о продукте

- Особенность

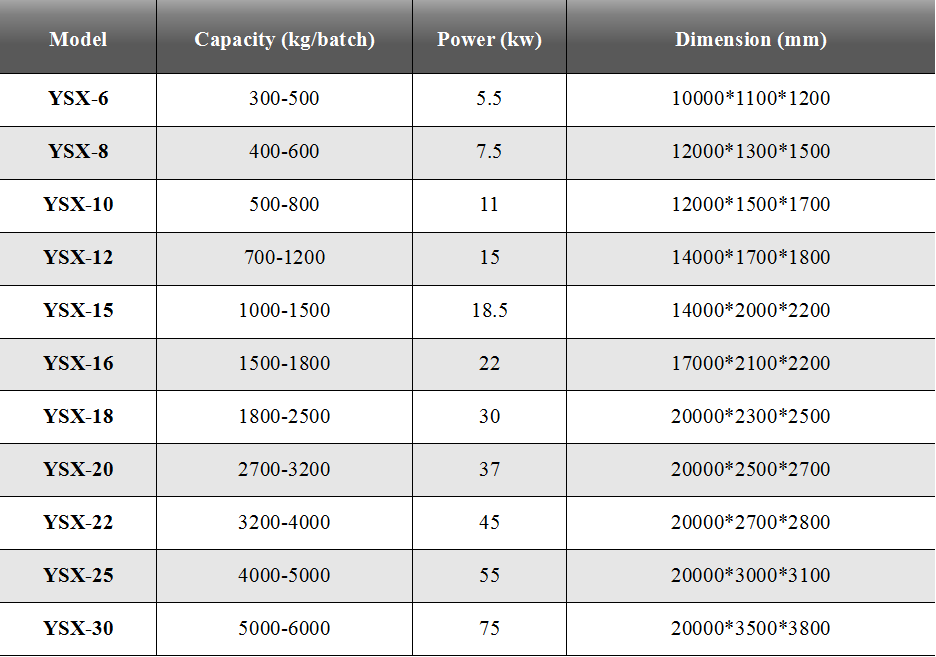

- Параметр

- Приложение

- Запрос

- Низкий инвестиционный бюджет, Требуется небольшая площадь земельного участка, простое управление, Бесплатное обслуживание.

- Он подходит для многих видов твердых отходов, таких как сельскохозяйственные отходы, Бытовые отходы, Электрические отходы, и так далее.

- Выделяемый при карбонизации дымовой газ может быть вспомогательным топливом для обогрева угольной печи, что может снизить общие эксплуатационные расходы.

Линии по производству древесного угля периодического действия, как правило, меньше по размеру по сравнению с методами непрерывного производства и хорошо подходят для коллективного или децентрализованного производства древесного угля. Угольные машины периодического действия относительно просты и экономичны, что делает их пригодными для небольших операций или в районах с ограниченными ресурсами, Они обычно используются в сельской местности или в децентрализованных условиях для местного производства древесного угля.

Машина для карбонизации,Машина для производства древесного угля

Машина для карбонизации,Машина для производства древесного угля